dddhhhAutomatic cut to length machine is an efficient metal processing line used to cut metal coils into metal flat sheets. The raw materials suitable for automatic cut to length lines include hot-rolled steel, cold-rolled steel, galvanized steel, color-coated steel, high-strength steel, stainless steel, aluminum, copper and alloys, etc.

Usually, metal coils are uncoiled, leveled, cut to length and blanked. KINGREAL SLITTING can provide a full range of automatic cut to length machines by combining different components according to the specific needs of customers. The design and manufacture of each automatic cut to length line are customized according to customer needs. When choosing a suitable automatic cut to length machine, specific factors such as production capacity, operating speed, material thickness and width need to be considered. KINGREAL SLITTING automatic cut to length lines are strictly inspected for quality and standards before being delivered to our valued customers.dddhhh

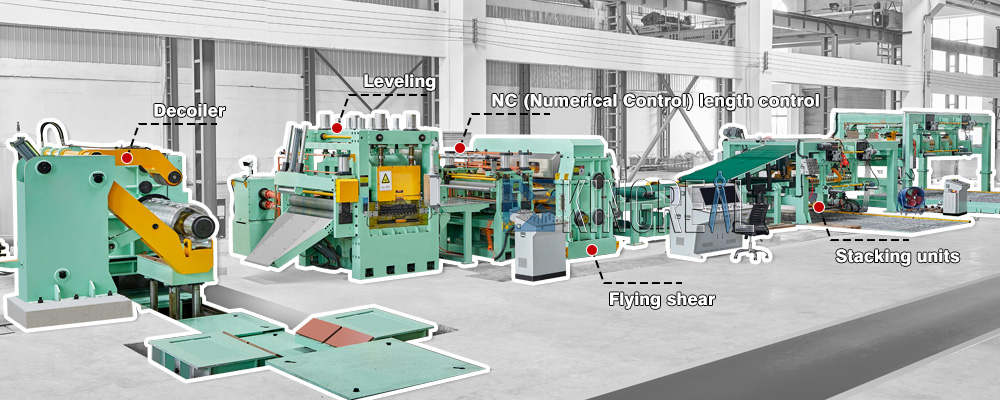

1.Workflow of Automatic Cut to Length Line

The steel coil is transported to the decoiler by the feeding trolley. From the decoiler, the strip passes through a high-precision leveler, which is designed to level the steel to the required material thickness range and yield strength. The strip then passes through a squaring device and precision roller feeder to the high-speed shear, where it is cut to the required length. The cut sheets then move to the automatic stacker.

2.Parameter of Automatic Cut to Length Machine

| Model | Model 1 | Model 2 | Model 3 | Model 4 |

| Coil Material | δs≤230N/mm2,Cold-rolled Coil, Stainless Steel Coil, Galvanized Coil ,AL ,Copper | |||

| Coil Thickness | 0.11~1.2mm | 0.2~2.0mm | 0.3~3.0mm | 0.5-4.0mm |

| Coil Width | 300~1250mm | 800~1250mm | 800~1250/1600mm | 800~1600/1800mm |

| Coil Weight | 10T | 20T | 20T(25T) | 25T(30T) |

| Coil I.D | ф508mm | ф508mm | ф508&ф610mm | ф508& ф610mm |

| Coil O.D | ≤ф1800mm | ≤ф1800mm | ф2000mm | ф2000mm |

| Cutting Range | 300~3000mm | 300~4000mm | 300~4000mm | 300~4000mm |

| Cutting Accuracy | ±0.3mm | ±0.3mm | ±0.5mm | ±0.5mm |

| Roller Diameter | ф65(50) | ф65(50) | Ф 85(65) | Ф 100(80) |

| Linear Speed | 0~60m/min | 0~60m/min | 0~60m/min | 0~60m/min |

| Control System | PLC Automatic control | |||

3.Advantages of Automatic Cut to Length Machine

3.1 High efficiency automatic cut to length machine

The automatic cut to length line is composed of a variety of precision components, which can significantly improve production efficiency. Compared with the traditional shearing method, automatic cut to length machinenot only saves human resources, but also helps to shorten the production cycle. The operator only needs to supervise on the side to ensure the safe operation of the automatic cut to length line and deal with emergencies in time. The automated operation of the automatic cut to length machine makes the production process smoother and reduces the impact of human factors on efficiency.

On the automatic cut to length line, the operator only needs to enter the relevant parameters on the control panel, set the cutting length and quantity, and the system can automatically complete the subsequent work according to the preset program. This efficient production method not only improves production capacity, but also reduces labor costs, enabling enterprises to gain an advantage in the fierce market competition.

3.2 High flexible automatic cut to length machine

The automatic cut to length line can handle a variety of materials and metal coils of different thicknesses to meet the needs of different industries. KINGREAL SLITTING has specially designed three automatic cut to length lines, targeting the processing needs of metal coils of different thicknesses:

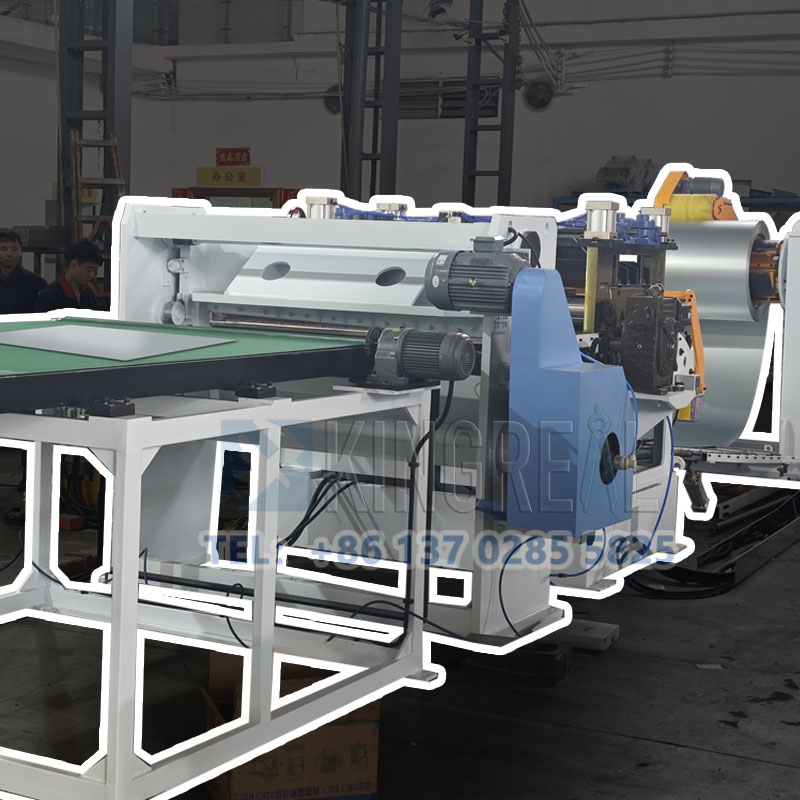

·Light gauge cut to length line: can process metal coils with a thickness of 0.3-3mm, which is very suitable for the processing of light metal.

·Medium gauge cut to length line: suitable for processing metal coils with a thickness of 0.3-6mm, and flexibly responding to the production needs of medium thickness.

·Heavy gauge cut to length line: can process metal coils with a thickness of 6-20mm, meeting the requirements of heavy metal processing.

This targeted design enables the automatic cut to length line to be widely used in many fields such as automobile manufacturing, construction, and home appliances, greatly improving the applicability and market competitiveness of the automatic cut to length machine.

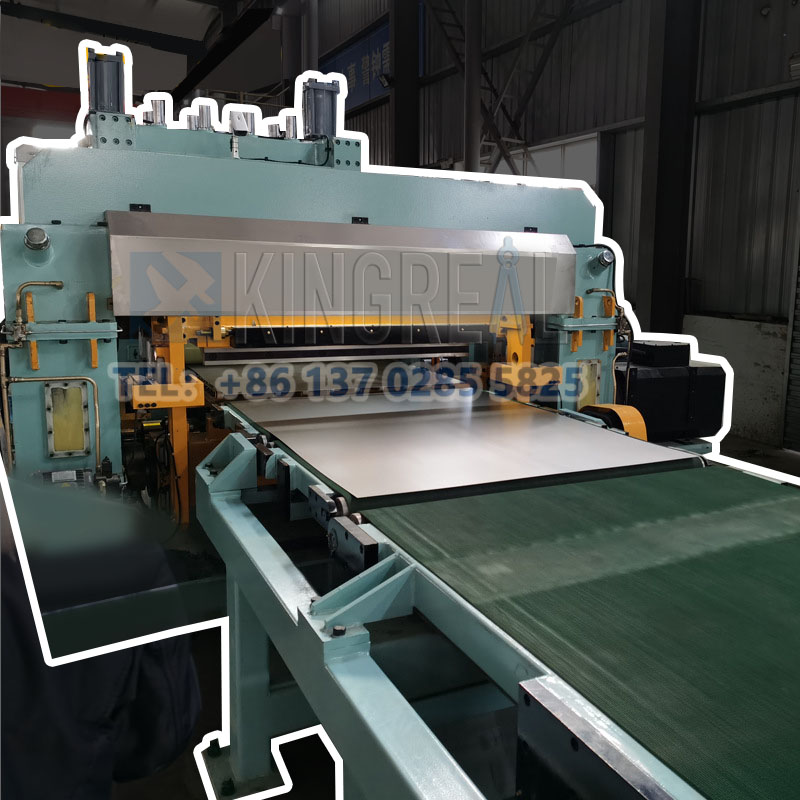

3.3 Precision cutting

KINGREAL SLITTING automatic cut to length machine uses high-hardness, wear-resistant blade materials to ensure high precision during the cutting process. This blade is not only durable, but also maintains its cutting performance during long-term use. By entering the relevant parameters on the control panel, users can easily set the preset length, and the automatic cut to length line will automatically perform high-precision shearing.

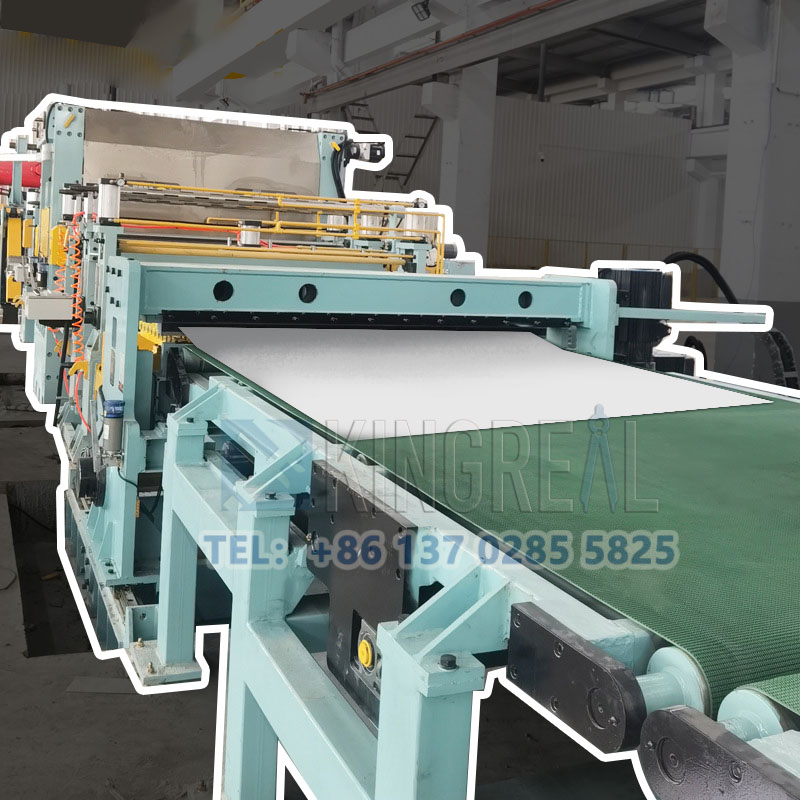

3.4 Automatic cut to length lines with diverse shearing methods

In order to meet the production needs of different customers, KINGREAL SLITTING has designed automatic cut to length machines with various shearing methods, including flying shearing cut to length line, rotary shearing cut to length line, swing shearing cut to length line and fixed shearing cut to length line. These different types of automatic cut to length machines have their own characteristics and can meet various production requirements.

Flying shearing cut to length machine:high-speed shearing, suitable for mass production.

Rotary shearing cut to length machine: efficient cutting through rotating blades, suitable for shearing of complex shapes.

Swing shearing cut to length machine: adopts swing shearing method, which can effectively handle thicker metal.

Fixed shearing cut to length machine:it will stop when shearing, and the speed is relatively slow, which is suitable for customers with small production scale or no high requirements for production efficiency.

Among them, the production speed of flying shearing cut to length line, rotary shearing cut to length line and swing shearing cut to length line can reach 80m/min, while the speed of fixed shearing cut to length line is 50m/min because it needs to stop for cutting. Customers can choose the appropriate automatic cut to length machine according to their actual production needs and product characteristics to achieve the best production effect.

In this article, KINGREAL SLITTING introduces the relevant information of automatic cut to length line. If you need to obtain more parameters or video materials about automatic cut to length line, please feel free to consult KINGREAL SLITTING! KINGREAL SLITTING has a strong 24-hour online team that can give you professional and fast response.