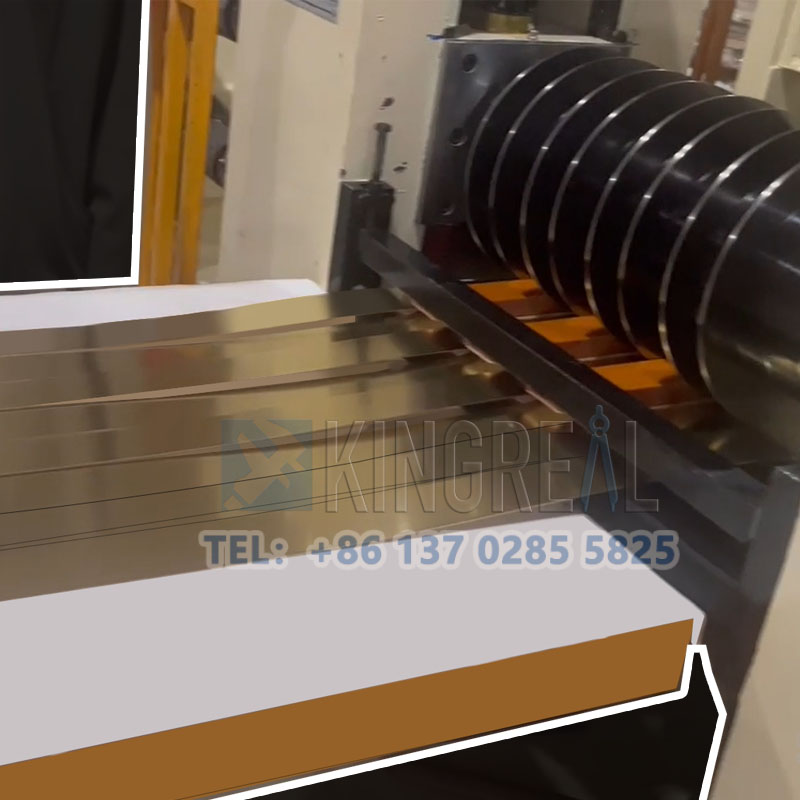

1. Coil slitting machine Shipped to Italian Customer’s Factory

Last week, KINGREAL SLITTING successfully completed the manufacture of a coil slitting equipment. After rigorous machine testing and precise measurement, the staff confirmed that the equipment can stably produce narrow metal strips that meet customer requirements and achieve the expected slitting speed, ensuring that the performance of the machine fully meets the customer's production needs. After a comprehensive inspection, the coil slitting machine was officially judged as a qualified product and was successfully shipped to the Italian customer's factory.

Before shipment, in order to ensure that the coil slitting machine remains in good condition during transportation, the KINGREAL SLITTING team carefully packaged the various components of the coil slitting machine. By using reinforcement materials and protective measures, the risk of component damage due to possible collisions during transportation is minimized.

2. Parameters of this coil slitting equipment

| Thickness | 0.3-5MM |

| Coil Material | Gi steel, Hot-rolled steel, Cold-rolled steel, PPGl |

| Coil Width | 1650MM |

| Slitting Speed | 230/Min |

3. Advantages of KINGREAL SLITTING's coil slitting equipment

KINGREAL SLITTING coil slitting machine provides customers with efficient and reliable metal slitting solutions with its flexibility, high precision and fully automated technology. The following are the main advantages of KINGREAL SLITTING coil slitting machine:

(1) Flexible solution

KINGREAL SLITTING provides a variety of combinations of coil slitting equipment according to the actual production needs of customers:

- Different speed ranges: meet the slitting needs from medium speed to high speed.

- Power consumption range: optimize energy utilization and reduce operating costs.

- Metal slitting capacity range: adapt to the slitting of coils of different materials, widths and thicknesses.

- Price range: provide customers with economical and high-performance options to meet different budget needs.

In addition, the KINGREAL SLITTING coil slitting machine can flexibly adapt to a variety of material widths and thicknesses, providing customers with customized solutions to ensure that their production needs are fully met.

(2) Fully automated design

The KINGREAL SLITTING coil slitting equipment integrates advanced automation technology and can fully control the entire production process:

- Quality control function: Through automated monitoring and adjustment, ensure that the slitting products meet high quality standards.

- Precision automatic longitudinal shear head: Achieve efficient and accurate slitting processing.

- Automatic tension control: Effectively avoid material deformation or breakage caused by uneven tension.

The application of automation technology not only improves production efficiency, but also eliminates the errors and efficiency fluctuations caused by manual operation, greatly improving the stability and reliability of production.

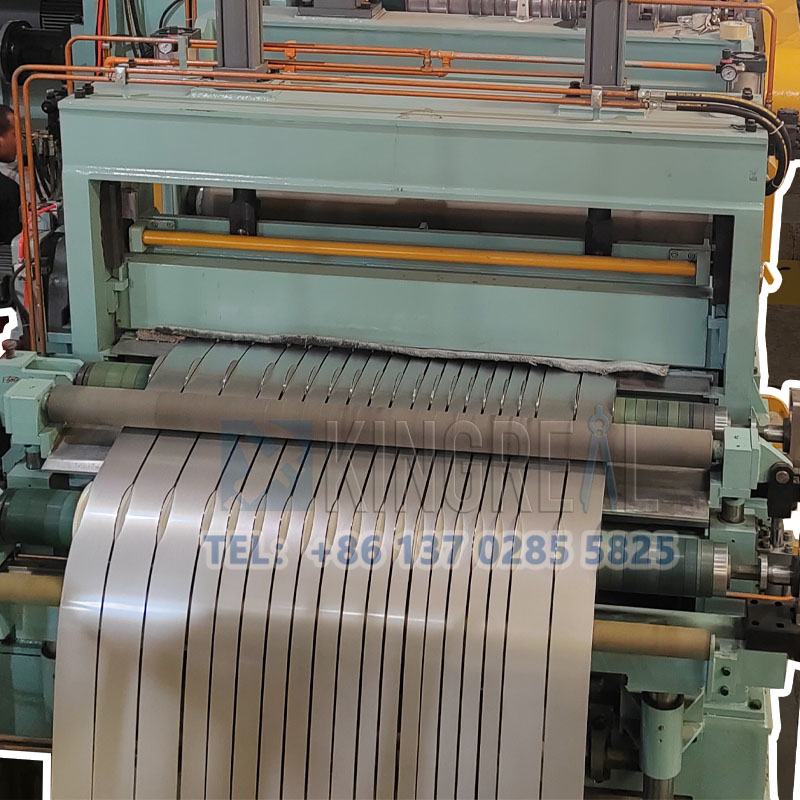

(3) High-precision slitting

The narrow strips slitting out of the KINGREAL SLITTING coil slitting machine have extremely high precision:

- The precision error range is controlled within ±0.1mm, meeting high-standard processing requirements.

- During the slitting process, there are no scratches or damage on the surface to ensure product quality.

This high-precision slitting capability is particularly suitable for industries with strict product quality requirements, such as automotive manufacturing, aerospace and other fields.

(4) Innovative winding technology

KINGREAL SLITTING coil slitting machine is equipped with a movable brake device to optimize winding performance:

- The winding diameter is increased to adapt to the processing of more specifications of materials.

- High winding accuracy ensures the neatness and consistency of the finished coil.

- The winding machine has a simple design and does not require a complex separation system, which reduces maintenance costs and improves operational convenience.

(5) Efficient multi-strip slitting capability

KINGREAL SLITTING coil slitting equipment supports slitting multiple narrow strips at one time:

- It can slitting multiple strips at the same time, greatly improving production efficiency.

- For more efficient slitting needs, KINGREAL SLITTING engineers can upgrade the equipment to enable it to handle the slitting of more narrow strips at the same time to meet the requirements of mass production.